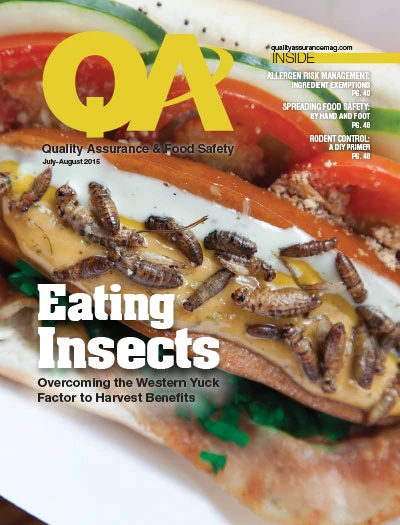

Most food companies are concerned with insects as adulterants in the products they produce. But a new wave of food products is intentionally including insects and labeling them as a key ingredient in the food. To expose the industry to this evolving food option, this QA Profile focuses on the breeding and manufacturing of insects as human food, its founding as a sustainable food option, the food safety and quality aspects of these unique products, and the challenges of overcoming the Western “Yuck Factor” to turn these sustainable foods from trend to mainstream. To get to the meat of the story (so to speak), QA Editor Lisa Lupo toured Big Cricket Farms, the first U.S. edible-insect farm; visited with the founder of Chapul, the manufacturer of the first U.S. commercial insect-flour product; and, yes, had her first bite of crickets—both crunchy whole and as a protein-rich ingredient. (See ViewPoint)

Most food companies are concerned with insects as adulterants in the products they produce. But a new wave of food products is intentionally including insects and labeling them as a key ingredient in the food. To expose the industry to this evolving food option, this QA Profile focuses on the breeding and manufacturing of insects as human food, its founding as a sustainable food option, the food safety and quality aspects of these unique products, and the challenges of overcoming the Western “Yuck Factor” to turn these sustainable foods from trend to mainstream. To get to the meat of the story (so to speak), QA Editor Lisa Lupo toured Big Cricket Farms, the first U.S. edible-insect farm; visited with the founder of Chapul, the manufacturer of the first U.S. commercial insect-flour product; and, yes, had her first bite of crickets—both crunchy whole and as a protein-rich ingredient. (See ViewPoint)

Why Should We Eat Bugs?

Bugs could be called a SUPER food. They are:

Sustainable—In 2013, FAO published a 200-page document on the contribution that entomophagy makes to food security and the prospects of increased commercial production. As the report states, insects are a promising alternative to the conventional production of meat, for both human consumption and animal feed. For example, studies have found that insects are twice as efficient in converting feed to meat as chickens, at least four times more efficient than pigs, and 12 times more efficient than cattle. (See In 2050: Can We Feed the World, May/Jun QA, bit.ly/1Lr9psO, for more on this topic.)

Why Don’t We Eat Bugs? The long and short of it is that Western Cultures (Europe and North America) don’t eat insects because our ancestors didn’t, so we were not raised to do so and we developed a cultural aversion. In fact, while 80% of the world’s population eats insects as food, Western cultures—and our food regulating agencies—see insects primarily as adulterants in food. By some accounts, it is an evolutionary factor of the colder climates of the northern latitudes of these peoples. Because insects do not survive well in the cold, they would have been less accessible as a food for our ancestors who migrated north. That said, many native American tribes did incorporate insects into their diets, and some of the early settlers of Utah survived on prairie cakes made with katydid meal when their crops failed. However, as time moved on, it became a socio-economic factor as well. The perception is that: insects are pests; they are dirty and carry disease; they are strange in appearance and generate a shiver of disgust (or worse) when seen or accidentally contacted. Additionally, the Western world, in general, does not face a food shortage that would make it necessary to resort to eating bugs. With all that, the question has become more one of: Why would we eat bugs? |

Ultra-nutritional—Although the specific values vary by species, in general insects contain more protein, iron, and omega-3 acids, and they have 10 times the protein-conversion efficiency of cows and pigs. One estimate rates insects as having 15% more iron than spinach, two times the protein of beef, and as much vitamin B12 as salmon. Moth larvae, in particular, has the same amount of protein as beef, 35% more calcium, and 10 times more iron.

Palatable—Can 80% of the world’s population really be wrong? With more than 1,900 species of edible insects around the globe, there’s bound to be at least one or two that strike your tastebuds … once you allow yourself to move past disgust. Simply ask Florence Dunkel, Montana State University professor of entomology, host of several Bug Banquets, and daily entomophagist, who says: “Ant eggs? They’re wonderful!” If you simply can’t stomach the thought of eating bugs straight, companies such as Chapul provide a gentler introduction through the use of cricket-flour in energy bars.

Earthy—Insects are about as “natural” as it comes, with consumption of insects dating back as far as man has existed. Additionally, entomophagy is good for the Earth—with more than 1,900 insect species consumed around the world, it is a plentiful and resource-efficient food for which only Western cultures tend to have qualms. And, at its most basic, the taste of insects is often described as “earthy.”

Revolutionary—Entomophagy has moved beyond novelty but has not yet reached the level of mainstream. But the revolution is spreading, one cricket-savoring individual at a time. As Chapul Founder Pat Crowley said in a January 2015 TEDxZwolle (Netherlands) presentation:

- I beg you to consider theglobal impact of your daily actions, especially in relation to food.

- I challenge you to stand up tall, raise your voice loud when you decide to eat consciously.

- I dare you to be apirate of your own cultural habits and activities that don’t fit with a sustainable future.

- I invite you to join in the revolution—and add insects to your diet.

Rearing Crickets for Human Food

As the founder of first farm in the U.S. to raise crickets solely for human consumption, Kevin Bachhuber has faced challenges, learned lessons, and shared knowledge with cricket farmers and government officials as far away as Brussels, Belgium. And all this in only the little-over-a-year that Big Cricket Farms has been in operation in Youngstown, Ohio.

Crickets have been commercially reared in America for bait and feed for more than 65 years. And today’s general production methods aren’t all that much different, except, Bachhuber said of his facility, “It’s like a space-age version of a traditional cricket farm.” Thus, while there are lessons to be learned from tradition, there are a number of differences between human food and feed production in quality and quantity and the impact of these on production methods.

The primary production difference occurs after the rearing of the crickets. That is, pet stores and other buyers of crickets as feed want the crickets to be provided live. Food buyers, on the other hand, want the crickets dead and ready to process.

The primary production difference occurs after the rearing of the crickets. That is, pet stores and other buyers of crickets as feed want the crickets to be provided live. Food buyers, on the other hand, want the crickets dead and ready to process.

Cricket “slaughter” is conducted through freezing. Once harvested, the crickets are put into a freezer at a temperature which causes them to go dormant. Once in this state, the temperature is further lowered causing their death. When completely processed, the frozen crickets are removed from the freezer, rinsed and strained to remove the legs and antennae. “Those can get caught in your teeth,” Bachhuber said. But nothing goes to waste—the legs, antennae and molted skins are sold to fish farms, and the cricket excrement is sold as a fertilizer. The finished crickets are then weighed and packaged in vacuum sealed bags, and sold as a raw food ingredient.

Humane Treatment. It is a humane process which meets the laws of kosher food, said Bachhuber, who is a devout member of the Jewish faith. “Kosher is important to me,” he said. “A lot of Kosher is about not ingesting anything that has suffered, so I addressed humane treatment in the initial building plan.” Additionally, Bachhuber said, “My priority is the bugs. My customers can conform to the needs of the insect.”

One may not immediately think to equate crickets with humane treatment and limiting stress, but both are important in their rearing because they are living animals and, just as with cows, pigs, chicken, and other animals raised as food (See Animal Welfare with Temple Grandin, QA Nov/Dec 2009, bit.ly/1GtOZty), the “meat” of crickets that undergo stress will be of lesser quality.

One may not immediately think to equate crickets with humane treatment and limiting stress, but both are important in their rearing because they are living animals and, just as with cows, pigs, chicken, and other animals raised as food (See Animal Welfare with Temple Grandin, QA Nov/Dec 2009, bit.ly/1GtOZty), the “meat” of crickets that undergo stress will be of lesser quality.

There are four ways that crickets communicate—through dance, chirping, antennae fencing, and pheromones; a change in any of these can indicate stress. “If we catch a whiff of unhealthy cricket smell, we immediately try to figure out what is causing the stress.” If needed, crickets will be placed in the “hospital tent,” where the environment is very tightly controlled and the crickets continually monitored.

The most common problem is air quality or improper humidity levels. Additionally, if a group of crickets molts faster than expected, the population density can get too high, causing overcrowding or limited food and water access. “If the crickets become stressed, it will impact the quality and taste,” Bachhuber said. So if a group does become so stressed that he expects it to have an impact, those will be sold to a fish farm rather than processed as food.

Big Cricket Farms rears Tropical (Banded) House Crickets (Gryllodes sigillatus)—one of three species certified for U.S. transport, Bachhuber said. The farm rears its crickets from eggs, which are set in their own segregated bin. The number of crickets in each bin is dependent primarily on the insect stage of growth.

“Crickets are a lot like people,” he said. “The young cluster together, but as they get older, they need a lot more personal space.” Thus, there may be 10,000 or 100,000 crickets in a single bin, with about 20 million crickets in the 5,000 square-foot facility—where a new tented area is currently under construction that will significantly increase the company’s capacity.

Regulation. FDA and USDA, as well as the food regulators of Canada, Europe, and other countries, have not yet set regulations for insects as food, so there are a lot of grey areas. The closest anyone has come is that the insect must be declared on the ingredient label by its common and its Latin names, and producers need to follow standard GMPs related to food. Additionally, because those who are allergic to shellfish are likely to also be allergic to insects, products must include allergen declaratory statements.

Regulation. FDA and USDA, as well as the food regulators of Canada, Europe, and other countries, have not yet set regulations for insects as food, so there are a lot of grey areas. The closest anyone has come is that the insect must be declared on the ingredient label by its common and its Latin names, and producers need to follow standard GMPs related to food. Additionally, because those who are allergic to shellfish are likely to also be allergic to insects, products must include allergen declaratory statements.

Because Big Cricket Farms produces an animal product for food, it is inspected by USDA. But, at this point, the visits are as much a working-out of the regulations and a partnership, as they are an inspection.

The issue of regulation is, in fact, a global concern. As the FAO publication states, “Regulatory frameworks governing food and feed chains have expanded tremendously in the last 20 years; however, regulations governing insects as food and feed sources are still largely absent. For developed countries, the absence of clear legislation and norms guiding the use of insects as food and feed is among the major limiting factors hindering the industrial development of farming insects to supply the food and feed sectors.”

Bachhuber follows GMPs, has a HACCP plan, and abides by animal slaughter requirements. For example, USDA regulations state that the slaughter area must be maintained separately. So Big Cricket Farms’ freezers are in a separate room. Although the farm currently uses a freezer similar to the uprights of foodservice firms, Bachhuber is building out a large walk-in freezer that will go a long way toward enabling increased production.

Bachhuber follows GMPs, has a HACCP plan, and abides by animal slaughter requirements. For example, USDA regulations state that the slaughter area must be maintained separately. So Big Cricket Farms’ freezers are in a separate room. Although the farm currently uses a freezer similar to the uprights of foodservice firms, Bachhuber is building out a large walk-in freezer that will go a long way toward enabling increased production.

“The government likes that we have a three-shell containment system,” he said. This consists of (1) the bins in which the crickets live, (2) the tented structures enclosing the bins, and (3) the production facility itself.

Product Quality. Big Cricket Farms does not grind its crickets to flour, rather it sells its frozen de-legged, de-anntennaed crickets as a gourmet food, primarily to foodservice companies such as Suzie’s Dogs and Drafts which cooks up the crickets as a hotdog topping. “According to the popular view, my bugs taste too good (to be flour),” Bachhuber said. Which leads to another key difference between feed and food crickets: that is, the food they are fed. The crickets of Big Cricket Farms are organically fed with a feed that is nutrient dense. The crickets could be grown more quickly with a less nutritious feed, but that would also cause them to be more fatty, lowering the quality of the final product.

The company is currently providing a forum for a Youngstown State University graduate student to conduct research on the cricket feed. Once hatched, crickets need to digest a certain amount of food to molt through five nymphal stages (or instars) to become an adult. (Unlike insects that go through a larval stage, baby crickets resemble white versions of their adult counterparts right out of the egg.) One goal of the research is to determine if a feed could contribute to faster molting without sacrificing quality or nutrition.

During the last two days before harvest, the crickets are fed vegetables and herbs. This not only increases the quality, it impacts the taste of the crickets, as the insects take on the flavor of the food they eat, Bachhuber said. “My favorite is the cilantro.”

This is not to say, however, that Bachhuber will never produce cricket flour. In fact, a next step in his company plan is to expand into another facility and produce cricket powder for flour.

Food Safety & Quality. While insects are said to be less likely to transmit zoonotic disease than are other animals raised for food, there are some unique safety challenges that go along with insect production.

One of the most important, Bachhuber said, is the use of an air scrubber to filter and regulate the air within the facility. When there are high populations of hatching crickets, they will release a predatory gas that causes tunnel vision and system depression in people. “We initially thought it was just from spending so much time at work,” Bachhuber said. The pheromones released by the crickets also can have an aphrodisiac effect on humans … as at least two not-to-be-named employees discovered before the facility installed its air scrubber.

Another quality assurance aspect of rearing crickets is the potential of dermestid beetles and other insects which are attracted to the cricket excrement. When asked how they get rid of them, Bachhuber replied with a preventive approach: “Quality assurance is assuring we never have the problem in the first place.” This “first place” starts with the strict control of the supply chain, and the cleanliness and quality of the eggs that are brought in. From thereon, it is a matter of keeping the bins clean, freezing the cricket’s food before use, and keeping a watchful eye for non-intentional insects, Bachhuber said, suddenly exclaiming, “Oh … Is that a fly?!” as he peered down into a bin of recently hatched cricket nymphs. “Is it? … I think I see something moving … No, I guess not, it must have just been my eyes …”

Another issue is cricket viruses. While it didn’t get the publicity of the recent Avian Flu which significantly reduced the egg-laying chicken population, the 2010 outbreak of cricket paralysis virus (CPV) decimated much of the feed cricket population. Not only is there no cure for CPV, it is so persistent that multiple cleanings of a facility cannot always eliminate it, and workers, who cannot contract the virus, can continue to pass it to cricket populations.

Thus, when his crickets contracted a virus in 2014 that killed six million in 21 days, there was a lot of panic in the facility, Bachhuber said. Thankfully, a cricket virologist was able to diagnose it as a picornavirus, which is much less severe and much easier to eliminate.

Maintaining sanitation throughout the facility, keeping the cricket bins raised up off the floor and out from the walls, wiping down all walls weekly, following other standard GMPs—and ensuring its suppliers do so as well, also helps Big Cricket Farms maintain a food-safe facility.

With a penchant toward natural foods, Bachhuber see entomophagy as a nutritious and sustainable food option that he hopes will continue to expand in acceptance across the Western world. However, he said, “I don’t see bugs as a cure-all to world hunger, but I definitely see them as a link in the chain.”

Manufacturing Cricket Foods

In the language of the Aztecs, Chapul means cricket (or grasshopper). It was Pat Crowley’s learning of this native tribe’s tradition of avid consumption of chapul and other insects, his career of and concern for water-resource conservation, and the knowledge of insects as a more sustainable, resource-efficient form of food that led the degreed hydrologist to found Chapul—“the original cricket-bar manufacturer” and the first consumer product to promote insects as nutrition, Crowley said.

Changing the ingrained culture and habits of a people is not an easy task, and changing the psychology of the Western world to accept insects as food was destined to follow this same difficult road—despite the individual and world health benefits.

But from its crowdsourcing start—which elicited Kickstarter donations of $16,000 from 13 countries in just 19 days, to his appearance on Shark Tank, to extensive travel and promotion—including a TEDx talk in Zwolle, Netherlands, Pat Crowley has persevered and is changing Western minds “one cricket bar at a time.”

One cricket bar at a time. Crowley deliberately chose to manufacture an energy bar from cricket flour rather than producing a more insect-obvious product as a way of gently introducing the world to insect consumption. The thinking follows that of the introduction of sushi into American culture in the 1960s. At that time, the consumption of raw fish evoked a similar disgust reaction as that of insect consumption today. Thus, the introduction of the California Roll. Not only does this roll not actually incorporate raw fish, the traditional nori (seaweed) wrapper was moved to the inside of the rice to provide the taste without the appearance.

In the same way, Chapul’s cricket bars provide a gentle introduction to entomophagy, enabling Westerners to say, “Yes, I’ve eaten insects,” without having to actually see the cricket ingredient or even get an overwhelming taste of cricket over the Thai, Aztec, and Chaco bar flavors—flavors that were chosen as representative of cultures that eat insects. “We knew if we were going to introduce insects into the Western diet, we had to do it in a delicious way,” Crowley said. “So we created a California roll of insects.”

The Process. Chapul’s process begins where Big Cricket Farms leaves off. After purchasing frozen crickets from a cricket farm, the company thaws and rinses the crickets; cooks them on a sheet to dry them out; then mills them into a flour. At this point, there’s really very little difference between today’s process and that of the Aztecs, except that the ancient practice was to dry them in the sun, Crowley said.

The company spent a great deal of time developing a recipe for its first bar, wanting it to be healthy and tasty with a unique flavor profile. Crickets actually have a very mild flavor, he said, but adding nuts, berries, and fruits further enhance the flavors of the energy bar and, visually, provide the look of what Americans see as food. Additionally, the consumers of energy bars were those whom Crowley saw as most receptive to the company’s message.

Shark Tank. Crowley is the first to admit that he has an environmental background, not that of food or marketing. So, while he knew how to get the conversation started on an environmental level, he didn’t know the best way to sell food or market the product.

Shark Tank. Crowley is the first to admit that he has an environmental background, not that of food or marketing. So, while he knew how to get the conversation started on an environmental level, he didn’t know the best way to sell food or market the product.

So he decided to apply to the ABC series Shark Tank. Not only was he accepted and appeared on the show, he was selected by “Shark” Mark Cuban—resulting in Cuban’s March 2014 investment of $50,000 for 10% of the company. Since then, Cuban and his staff have been tremendously helpful, Crowley said, adding, “We would not be experiencing the growth that we are without them.” Growth such as the 10,000% surge in traffic to its website following the show, he said.

Overcoming the “Yuck.” Despite the individual health benefits, world sustainability statistics, and gentle introduction, overcoming America’s ingrained cultural yuck factor of eating bugs is a distinct challenge. This was proven even at the QA office where cricket-bar samples were offered. Barely 5% of GIE employees were willing to stop by and take a taste. But from those who did, the responses were all positive, ranging from: “They just taste like protein bars” and “There’s an earthiness to them, but I like them” to “They’re delicious.”

Montana State University Entomology Professor Florence Dunkel has experienced similar reactions at the MSU Bug Buffet at which chefs use her own home recipes for sautéed, stirred, and spiced bugs. An entomophagy connoisseur, Dunkel regularly dines on everything from butterfly larvae and mealworms to ant eggs (of which she says, “They’re wonderful!”) and, of course, crickets.

In her presentations on edible insects, Dunkel discusses their nutritional value—such as the comparison of moth or butterfly larvae to beef, with larvae being about equal in protein, but having 35 times the calcium and 10 times the iron; the cultural aspects of eating—and not eating—insects, including the embarrassment factor as well as that of the yuck; and the sustainability variance between insects and animals. (See Figure 1 and Figure 2 above.)

When deciding whether to eat insects, one should think about those which are already common in our foods:

- Red food coloring. Much of this is carmine/cochineal extract, that is, the dried body of the parasitic insect (Dactylopius coccus), with a 2009 FDA regulation mandated that this be declared on food and cosmetic labels by its common name.

- Figs. Figs are pollinated by the fig wasp, which lays its eggs inside the fig. The hatched females depart, but the males, who mate with the female inside the fig, do not leave. However their bodies are essentially digested by the fig to become part of the fruit as it ripens.

- Honey. While not technically an eating of the insect, honey is a product created by bees. But because we have been raised on its edibility, very few have any aversion to consumption of honey or its insect production—despite the fact that many retail products feature a bee on the label.

It is this same cultural acceptance factor of an insect product as food that works in the opposite way causing the non-acceptance of insects of food—until you make the deliberate effort to overcome it, put an insect in your mouth, and stop the disgust factor, Dunkel said.

“It’s not a novelty product, it’s very serious,” Dunkel said of insect food products. “We need to accept that it is just another kind of food—not super good or super bad; just different.”

The author is Editor of QA magazine. She can be reached at llupo@gie.net.

Explore the July August 2015 Issue

Check out more from this issue and find your next story to read.

Latest from Quality Assurance & Food Safety

- Chef Robotics Introduces Pat-Down Capability for Meal Presentation and Sealing

- USDA Launches Regenerative Pilot Program

- Indoor Ag-Con Adds Food Safety Track to Conference Lineup

- IDFA Recognizes Federal Officials for Support of U.S. Dairy Industry

- Tetra Pak Acquires Bioreactors.net

- Fresh Del Monte Receives Rabobank Leadership Award

- São Paulo Earns Guinness World Record for Largest Municipal Food Security Program

- KPM Analytics Releases Ready-to-Use NIR Calibration Packages