Invitrogen

www.invitrogen.com

Invitrogen’s Protein Production Transfection Kit contains three transfection reagents — FreeStyle MAX, 293fectin and Lipofectamine 2000 — for large-scale protein production. These reagents are optimized for specific production conditions, the company said, and come in convenient evaluation volumes, so you can test reagents for different production requirements. They also provide 6-10 times higher protein yield compared to other reagents, the company said.

The reagents are scalable from 30 millileters to 10 liters, and give plants predictable protein yields with little optimization required, the company said.

TandD

www.tandd.com

TandD has introduced the new TR-73U Data Logger, which monitors three channels: temperature, humidity and barometric pressure. This compact, lightweight unit is approximately 2 inches by 3 inches and operates on one AA battery.

There is a large, easy-to-read 4-digit display that shows all three channels. Front panel buttons control start, stop and setting of parameters. The TR-73U can store up to 8,000 readings in one-time or endless recording mode, the company said.

Simply by connecting to a computer via a USB port, the recorded data can be quickly downloaded. The product is an all-in-one package that includes the data logger unit, sensor and software.

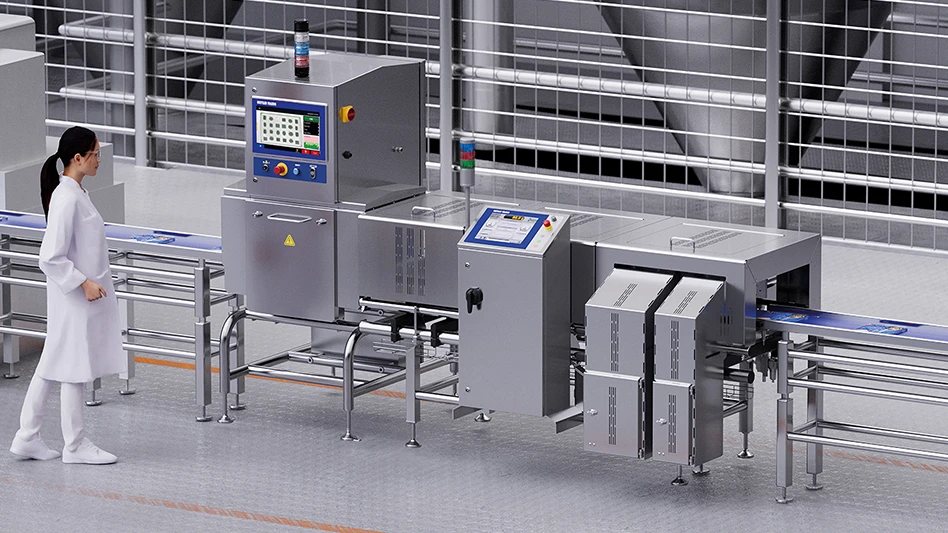

Applied Vision

www.appliedvision.com

Applied Vision Corporation announces new technology for its Genius inspection system that minimizes reflection on the lower sidewall of three-piece cans with easy open or converted ends.

When inspecting three-piece cans with easy-open or converted ends, features like rivets and scoring reflect back onto the lower sidewall of the container. These reflections obscure the image captured by the inspection system, making it virtually impossible to detect defects like scratches, coating voids, dents, foreign contaminants and oven dust, the company said.

Applied Vision’s new solution uses advanced lighting and optics to minimize the reflection on the sidewall. Specially-engineered software then filters out the remaining reflections, making critical defects visible to the system, the company said.

Rotex Global

www.Rotex.com/xd

Rotex Global announces the addition of the Megaetex XD Separator to its line of dry separation equipment. The Megatex XD is specifically designed to meet the demanding screening requirements of high-volume applications.

The Megatex XD features a high-capacity per square foot of screen cloth in a compact footprint, a screen deck slope of 6 degrees to meet demanding product specifications and maximize screen efficiency, and an external drive cartridge that allows continuous operation up to 400° F (205° C), the company said.

The Megatex XD also features a patented lift-rail system with non-binding, stainless steel cam activation for easy screen frame installation and removal, the company said. Newly developed easy-press fit silicone D seals provide exceptional sealing between screen decks.

The separator has a quick-opening discharge door that provides access to each individual screen deck for inspection and change-out. The stacked multiple deck, tray-access design allows access to these individual screens without the need to remove all decks at once, the company said.

Explore the January 2008 Issue

Check out more from this issue and find your next story to read.

Latest from Quality Assurance & Food Safety

- MARTOR Releases Metal Detectable Holster for SECUNORM 610 XDR

- FDA, CDC Investigate E. Coli Outbreak Linked to Organic Carrots

- USDA and Montana Award $3.1 Million to Projects That Strengthen Food Supply Chain Infrastructure

- PTNPA to Host Webinar Unveiling Post-Election Insights for Nut Industry

- Keep Food Safety in Mind This Thanksgiving

- FDA Updates Guidance for Voluntary Qualified Importer Program

- IDFA Announces 2025 Women's Summit

- Submissions Open for IAFP’s European Symposium on Food Safety