Allergens are a significant health risk for individuals allergic to certain foods. The Food Allergy & Anaphylaxis Network (FAAN) estimates that approximately 200 people die from anaphylaxis due to food allergies each year in the U.S. Allergic reactions occur when the body identifies a substance in the food, usually a protein, as a harmful substance. The body then creates antibodies to attack the harmful substance, which can cause mild to significant health issues ranging from itchy rashes and swelling to anaphylactic shock which can be fatal.

The U.S. has declared eight food allergens (Big 8) to be of most concern, including milk, wheat, peanuts, tree nuts, fish, shellfish, soy, and eggs. These foods were identified because they cause about 90% of food allergenic reactions in the U.S.

Allergens are a serious hazard in the food industry. In 2016, there were more than 700 food recalls and nearly 300 of them were due to undeclared allergens in food products. The only way an individual can determine if an allergen is in a certain food product is to read the label. If the allergen is not on the label, then the customer believes this product is safe to consume. If an allergen is or has the potential to be in a food product and is not listed on the label, it is considered an undeclared allergen.

Undeclared allergens are allergenic ingredients that are in the product but not listed on the product label. This can occur from three different issues:

- A facility makes similar products with slightly different labels, and the wrong label gets placed on the wrong product.

- Re-work materials are mishandled and allergenic ingredients are accidentally placed in the wrong product.

- Formulation changes are not managed, either in the facility or with suppliers of blended materials.

Undeclared allergens can be prevented. Allergen control, approved suppliers, and rework management are just a few programs developed to assist with managing this risk.

A good allergen control program will help manage allergens in a facility. Components of a good allergen control program include receiving, transporting allergens within the facility, storing them in safe locations to prevent cross-contact, and ensuring allergenic ingredients are controlled to prevent accidental usage. This program also requires procedures to clean allergen spills to prevent cross-contact. Establishing and maintaining an allergen control program is essential to prevent this food safety risk.

A well-developed approved-supplier program manages allergen hazards that could occur from suppliers, specifically from ingredients and raw materials provided by suppliers. This program should establish good communication between the manufacturer and the supplier, to include any formulation changes that might include new allergens that were not present in old formulations.

Both USDA and FDA require that facilities manage allergens and prevent cross-contact and undeclared allergen issues. Both agencies have issued regulations and mandatory programs to assist in preventing this significant food safety risk. USDA has created several guidance documents to help prevent this hazard. Additionally, USDA asks facilities to address allergen control in HACCP food safety plans. FDA also has created numerous guidance documents for allergen control in food facilities. Per the newest Food Safety Modernization Act regulations, facilities must address allergen control in their food safety plans.

Researchers estimate that more than 15 million Americans have food allergies. One in 13 children under the age of 18 are affected by food allergens, and these numbers are on the rise. Researchers have yet to determine the cause in rising numbers of people affected by food allergies, however, with the increasing number of people affected and the increasing number of recalls related to undeclared allergens, this significant food safety risk has the potential to become more serious.

Establishing these basic food safety programs and managing allergen risks through required programs is important to help reduce the potential risk.

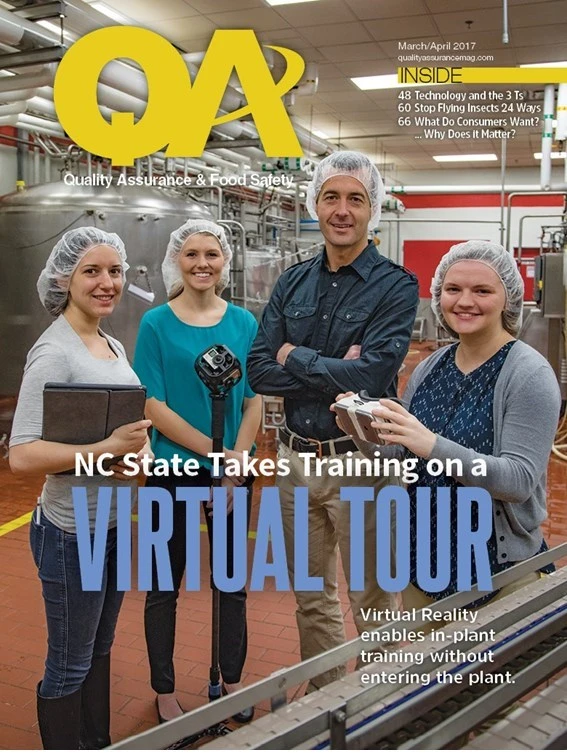

Explore the April 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Quality Assurance & Food Safety

- Boston Sword & Tuna Protects Seafood Safety with Mettler-Toledo Metal Detectors

- IFT Releases New Resources to Aid Food and Beverage Industry in Sugar Reduction

- Yum! Brands CEO David Gibbs to Retire in 2026

- Penn State Extension Offers Short Course on Food Microbiology and Safety for Food Plant Workers

- Johnsonville Recalls Cheddar Bratwurst Due to Possible Plastic Contamination

- Cabot Creamery Butter Recalled Due to Possible Fecal Contamination

- USDA Delays Salmonella Testing Program for Breaded Stuffed Chicken

- FDA Extends Comment Period on Poppy Seeds to June 16