Editor's Note: This article originally appeared in the January/February print version of QA under the headline "Ain't No Mountain."

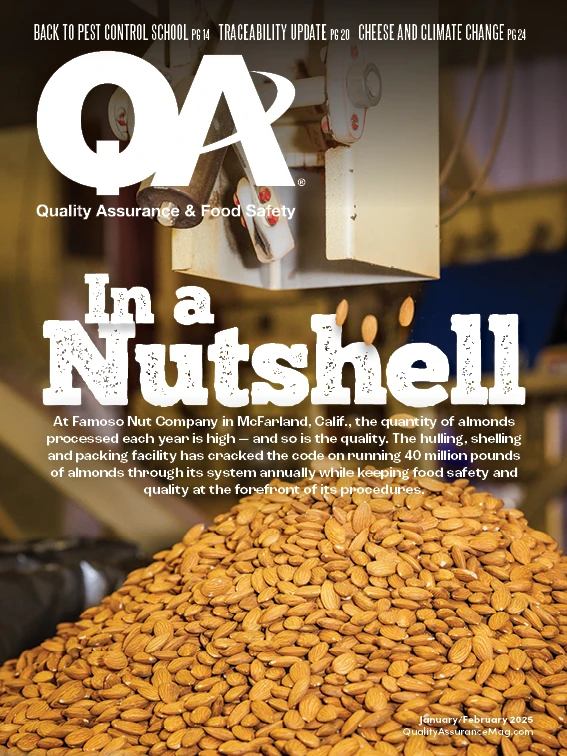

When I arrived at Famoso Nut Company’s processing facility in McFarland, Calif., last fall, I couldn’t help but gawk at the surrounding scenery — peaks and valleys illuminated under a blazing sun. No, I wasn’t admiring one of California’s mountain ranges. I was looking at almonds. Lots and lots of almonds.

All of the almonds awaiting processing at Famoso (the subject of our cover story) are heaped into enormous piles on an 80-acre stretch of outdoor storage space. The largest masses clock in at a whopping 1 million pounds. Craning my neck to watch the latest almond delivery rain down from a towering belt loader onto one of the piles, I was awestruck by the sheer magnitude of the operation.

As the Famoso team guided me through a tour of the company’s multiple buildings, it wasn’t just the quantity of almonds that left me astonished, but the precision involved in each step. From hulling and shelling, a nine-step process that removes the hull and shell from the almond as gently as possible to reveal the meat within without scratching the delicate skin, to a pass through the company’s latest addition — high-tech AI sorters that examine each almond for defects — every process at Famoso is carefully designed to ensure quality and deliver a high-grade product to their customers.

Paramount to that mission is a long-standing partnership with Sprague Pest Solutions, Famoso’s pest control provider (and the company that introduced QA magazine to the Famoso team), which implements innovative strategies such as a digital logbook to track pest issues in real time. Sprague’s team accompanied us on the tour to demonstrate their multi-pronged approach to managing the facility’s unique pest pressures.

After my visit with the Famoso and Sprague teams, I stopped by a café for lunch. About to dig in, I noticed the sliced almonds garnishing my Caesar salad. For the second time that day, I was overcome by a sense of wonder, equipped with the fresh knowledge that this tiny component of my meal, which I otherwise would have taken for granted, had traveled through so many steps to assure its safety and quality in its journey from the field to my table.

Explore the January/February 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Quality Assurance & Food Safety

- Chef Robotics Introduces Pat-Down Capability for Meal Presentation and Sealing

- USDA Launches Regenerative Pilot Program

- Indoor Ag-Con Adds Food Safety Track to Conference Lineup

- IDFA Recognizes Federal Officials for Support of U.S. Dairy Industry

- Tetra Pak Acquires Bioreactors.net

- Fresh Del Monte Receives Rabobank Leadership Award

- São Paulo Earns Guinness World Record for Largest Municipal Food Security Program

- KPM Analytics Releases Ready-to-Use NIR Calibration Packages