On-the-floor food-safety training in a processing plant can be a challenging proposition, requiring that the lines be shut down or the workers stay overtime, so as to enable training on what not to do as well as what to do and not introduce potential risk into production. Because of this, many processors prefer to keep as much training in the classroom as possible, limiting it to lectures and slides.

But what if there were a way to immerse food safety training into plant production without actually taking the workers out on the floor? What if there were a way to interest more university students in the area of food science by enabling them to experience a plant environment — without having to bus a class to the nearest willing facility?

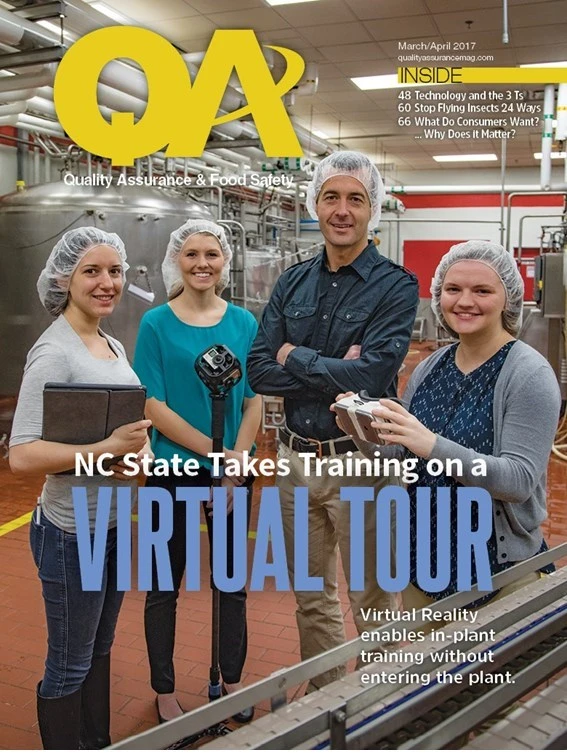

Working with North Carolina State Food Scientist Clint Stevenson and his team, Dean Foods and NC State’s Howling Cow Dairy have found a way: Virtual Reality.

With today’s TV commercials showing people in headsets flailing their arms or laughing giddily at something no one else can see, it is that which first comes to mind for many when mention is made of virtual reality (VR). But there is a great deal more to VR than that.

Essentially, Stevenson said, “When we say virtual reality, we’re creating an environment that’s a real image.” An environment in which a person is immersed and can interact for a variety of purposes in a multitude of ways through goggles or on-screen projection ... or both simultaneously.

“When you think of virtual reality, you think of putting on a headset. But with so many employees, that’s not feasible, so this was designed to be more usable,” said Instructional Designer Bethanne Tobey.

It also is important to have an alternative to the goggled headsets because statistics have shown that up to 40% of people can get vertigo when using the headsets for an extended time — with some feeling nauseated after even a minute or two of viewing. “People get excited about the headset, but it’s only cool if you don’t get nauseated,” said Instructional Designer Julie Yamamoto.

For the food processing industry, the purpose (which is becoming an extremely valuable educational tool) is that of virtual “on-site” food safety training. Immersed in the 360-degree, real-world environment of the food plant, the students or workers can follow the path of production from incoming goods through processing to packaging, or select specific areas of focus, interacting with the environment by looking for implanted food safety risks, clicking on “hot spots,” and gaining an in-depth understanding of the why, along with the how, of plant processes, practices, and standards.

HOWLING COW. Being able to see the plant and operations in action also enables participants to more easily understand — and the facilitator to explain — complicated matrices, changeovers, etc. And having a working dairy onsite has provided the team with a unique opportunity to stage food safety issues, show equipment breakdown and cleaning, and focus in on specific equipment. While the filming can disrupt the dairy operations, Howling Cow’s purpose is education, and “the dairy plant is just there to pay for research,” said Dairy Enterprise System Director Gary Cartwright.

With a number of firsts to its credit — getting FDA approval for hydrogen peroxide use in aseptic packaging, running the first microwave process, and being the first to mass-market a probiotic — the university dairy enterprise system has an illustrious history of industry contributions through its research. And with the system encompassing the entire chain, from growing the feed to a 179-cow dairy farm to milk and ice cream sales, Cartwright said, it provides students with real-world experience and allows researchers to plug into any part of the chain.

“We have an umbrella over the entire commodity,” Cartwright explained. “It’s a nice real world in a bottle.”

With its dairy products sold on campus, at the NC State Fair, to school districts, and to prisons, Business Operations Assistant Director Carl Hollifield focuses on the five M’s: “More milk means more money,” he said, adding, “The best thing they can do for quality is make it mean more profit.” And more profit means more research capability — including the VR work of Stevenson’s team.

IMMERSIVE TECHNOLOGY. It all started three years ago when Stevenson was teaching classes in quality assurance and felt the need to be able show online students the real world. In researching ways this may be able to be done, he saw the VR work of Mike Cuales. “My jaw dropped,” Stevenson said. “I saw I could present it online or in class and could point things out. I convinced him to come to the dairy plant,” he said.

With a contract from the North Carolina Department of Agriculture and Consumer Service, Stevenson’s team took video to the next level, integrating in-plant case studies, videos, and the immersive VR into an online course on Good Manufacturing Practices. Having been granted permission from the department to repurpose the course, Stevenson has continued furthering the development and use of the technology, working with his team of food science undergraduate and graduate researchers along with instructional designers.

It is a project which is not only enabling him to take his students into the food processing environment, but also is helping to build student interest in food science — a career area in which the industry is expecting workforce shortages of food safety professionals as Baby Boomers retire.

As such, Stevenson’s team is researching various aspects of the ways which VR can enhance food safety behavior as well as knowledge and skills. “As a lab, we talk a lot about food safety problems, such as how many of the recalls are due to human error,” Stevenson said.

THE VR EVOLUTION. Virtual reality training isn’t new; it has been used since the ’70s in various ways, such as the Department of Defense simulations and Duke University’s medical program. “What’s made this hot today,” Stevenson said, “is that you finally don’t need a multi-million-dollar project to create something.” Basic cameras can be purchased for $300 and cardboard goggles for less than $10.

Of course, like anything, you will get what you pay for, and without a solid training program to back it up, the “cool factor” will amount to little more than that. “The cool factor is awesome ... but what are the learning objectives of the program?” Stevenson said. It is for this reason that Tobey and Yamamoto are an integral part of the development team. “My first year on the job I learned that if we are creating training, we need sound instructional designers. As a food scientist, I knew very little about that,” Stevenson said.

The ability to use mobile devices and 3-D printers with the virtual reality systems is furthering the momentum of VR and putting it in the hands of faculty and teachers, Tobey said. With its vast range of uses — such as education, tours, long-distance training, entertainment, etc., she said, “We are still trying to figure out what is most applicable.”

But what is unquestionably applicable is the ability to put groups of students or workers into food-processing environments without the associated travel costs, safety issues, or processing disruptions. “We can bring the experience to them,” Tobey said.

Although it started with classes for NC State students and VR recording at Howling Cow, Stevenson’s team is now working with external food companies on the development of customized training for their workers, with local artisan cheese producers and Dean Foods as hallmark initiatives. (See VR Training for more on Dean Foods.)

INDUSTRY APPLICATION. Whether developed for an NC State class at Howling Cow or worker training at Dean Foods or another food facility, the virtual reality recordings are made on-site at active businesses. Then hot spots are integrated; food safety risks digitally staged, if desired; and facilitator directions added to enable classroom, small group, or one-on-one instruction. Participants interact with the training in various ways:

- They can explore the virtual plant seeing how various areas are set up and operate, stopping to zoom in on specific areas to more closely inspect equipment, lines, or a suspected risk.

- They can search out the staged risks and GMP lapses, noting each food safety issue found. When the goggle view is paired with the on-screen view, an interesting classroom exercise can be created as class participants explore along with the goggled student. They can cite any risks missed or applaud those noted. The pairing also enables the facilitator to guide or critique the trainee, as applicable.

- “Hot spots” can be integrated through interactive buttons on which the participant can click to look closer, discover more information or answer quiz questions. The pop-up text can focus on the equipment, the process, food safety needs, or any other information the plant would like highlighted.

INTO THE FUTURE. With the training tools compatible with standard tablet, mobile, or desktop screens, they are widely accessible for both educational and industry use. There also is a great deal of future evolution for VR training. For example, eye tracking through heat mapping can enable a facilitator or observer to see exactly where the participant’s eyes are focusing, adding a whole new range of potential dynamics.

“Through eye tracking you can see if the student is looking at what you want them to,” Yamamoto said. It also can enable hands-free movement of the cursor and “clicking” on the hot-spot buttons. Essentially, she said, “Your eyes become the mouse.”

One example Tobey cited was that of developing a mental model for training of food safety inspectors. What do they look at? Where are they focusing to inspect for common risks? “Let’s look at the pattern they follow,” she said.

While all this provides interesting and innovative evolution of the system, “our approach, so far, is let’s start simple,” Stevenson said. “Let’s start with an image in 360 — that’s enough in itself.” Stevenson admitted that this wasn’t his philosophy at the beginning; wanting to do everything possible with the technology, he was reined in by Tobey, who explained, “People will get lost if there’s not a clear path.”

Thus, it is Tobey and Yamamoto who have aided Stevenson in focusing on the learning objectives. “We have a lot of discussion about protecting food. Be smart; make it enjoyable — but meaningful,” he said, adding, “They keep me grounded. It’s a really nice combination: cutting edge, but keep it focused.”

ADDITIONAL RESEARCH. In addition to providing training, the VR project has led to numerous research initiatives by the team, including:

- A question being posed in a project by Undergraduate Research Assistant Caitlin Smits: Can you attract more students into the career field? Will virtually taking students into a food processing plant, enabling them to see the operation first hand and better understand the roles of quality assurance managers and food safety professionals, help to offset the expected shortage?

- Graduate Research and Teaching Assistant Stephanie Maggio has been focusing on food safety training for North Carolina’s small artisan cheesemakers. She worked with the processors to gain a true picture of their operations and training needs, then developed the training. The research is funded by the North Carolina Dairy Foundation to help ensure that even the smallest of operations are able to train employees on food safety even if they don’t have the economic means. The training is in beta, which she will evaluate, make any needed changes, and roll out.

- A project being conducted by Food Science Graduate Student Kristen Saniga focuses on evaluating the impacts of Dean Foods’ VR training and computer-based modules on its employee behavior and food safety culture. Saniga is looking at employee attitude, perception, knowledge, and self-reported behavior. “To what extent can training impact behavior?” she asks. “If we can develop a code of practice with Dean Foods and share it will others, it will help everyone.”

Although NC State is interested in working with food companies, that is not its primary purpose, Stevenson said. “We need to maintain a balance between taking on projects to help stakeholders, but also being here for students.”

It was a philosophy with which both the graduate and undergraduate students on the team agreed. “As an undergrad, I took his course,” Smits said. “There was a lot of information, but what I learned most from was when we went to the plant. That was so helpful, but it also takes time.” So the VR training provides that same understanding without the hour of travel, she said. “It’s that hands-on learning that so many universities are lacking and really need.”

Virtual reality training also helps dispel the “forgetting curve,” Stevenson said. People forget 80% of what they learn, but repetition of the information enables better and longer retention. Thus, while a single in-plant training session may result in only 20% retention of the information by a worker, “we can make VR reusable,” he said.

No matter how innovative, cool, and awesome the VR technology may be, its ultimate goal is to improve training, increase knowledge and skill, and change behavior. “We don’t want to touch it if it won’t achieve its objective,” Stevenson said.

The author is Editor of QA magazine. She can be reached at llupo@gie.net.

Explore the April 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Quality Assurance & Food Safety

- Ferrero Group Invests $445 Million in Ontario Production Facility

- Nelson-Jameson Announces Grand Opening for Pennsylvania Distribution Center

- Taylor Farms Linked to Romaine E. coli Outbreak as Marler Clark Files Multiple Lawsuits Against Supplier

- IAFNS Announces Winners of Emerging Leader Awards for Food Safety, Nutrition

- FDA Shares Testing Results for PFAS in Bottled Water

- Provision Analytics Adds Food Safety Expert Jennifer Williams to Strategic Advisory Group

- Boston Sword & Tuna Protects Seafood Safety with Mettler-Toledo Metal Detectors

- IFT Releases New Resources to Aid Food and Beverage Industry in Sugar Reduction