With more than 50 food supply, safety or labeling bills introduced and pending in Congress since the beginning of 2009, the industry can expect to see significant regulatory changes in tracking and traceability throughout the food chain from the passage of at least some of these regulations.

The extent of legislative oversight is still a recent trend for the food industry, which has been historically self-governing. However, such regulation is not unprecedented. In fact, said Katie Dowling, Solutions Consultant for Sparta Systems, the pharmaceuticals and life sciences industry (also FDA regulated) has been dealing with increasingly restrictive regulations and penalties for two decades.

Of particular significance, Dowling noted, is Title 21 CFR Part 11 of the Code of Federal Regulations, released in 1997. The regulation defines the criteria for electronic records and electronic signatures for those in drug and medical device manufacturing, as well as other bioscience companies, and could very well set the precedent for similar regulations in food.

In fact, FDA has already implemented regulations on mandatory electronic reporting of potentially dangerous foods and online registration of food facilities; and the Food Safety Modernization Act, having passed the House in 2009, has been expected to hit the Senate floor for months.

It is a change from the historically reactive approach of the food industry toward prevention. It is a change that includes a major focus on electronic tracking and standardization of traceability. And it is a change that will affect all producers, large or small, said Jack Sparn, CIO of Intelligent Global Pooling Systems (iGPS). "Government and regulatory requirements quite often do not differentiate between the size of the company or its balance sheet. All are under the same rules." As such, all food plants will need to invest in technology.

On the positive side, the costs of electronics and tracking products are coming down, he said, citing RFID and barcode labels as an example. The RFID tags were initially $5 to $6 in the 90s, but today, tags can be purchased for less than 10 cents. "Reading devices themselves are coming down in price, too—like computers," he said, noting that today’s $500 devices can do more than yesterday’s $5,000 units.

While Dowling agrees with the inevitability of system implementation, she doesn’t see it as happening overnight. Once a food safety bill is signed, she said, "it will probably take four to five years to come into play for all."

Dowling expects the agencies to first target larger companies that produce high-risk products—many of which already have pieces and parts of such systems in place, but that regulatory inspections will increase across the industry.

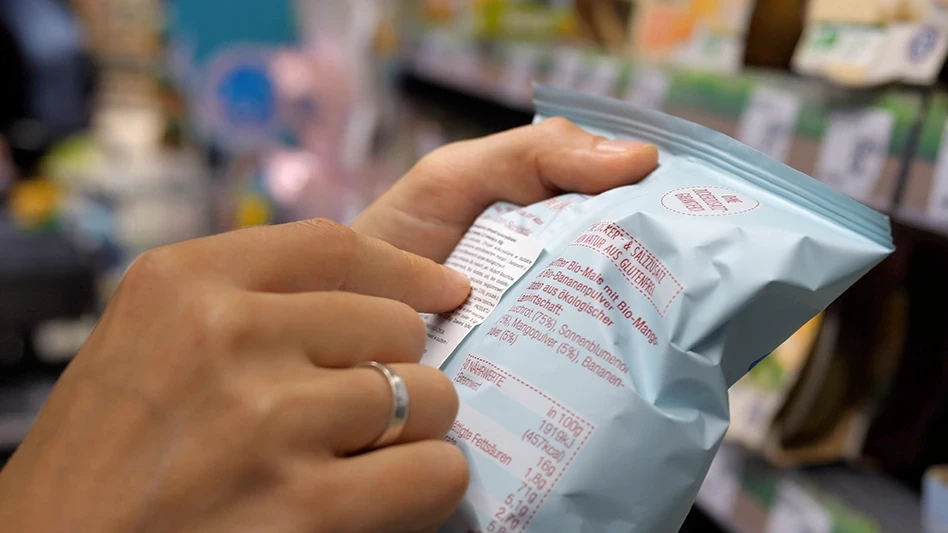

In the medical device arena, she said, FDA inspectors have been increasing their scrutiny of the supply chain. And that will hold true for food. "Sometimes that supply chain can be multi-layered," she said, using the example of a granola bar. "But ultimately whosever name is on that granola bar is responsible for that product.

"It goes back to better record keeping; better access to records."

Tracking System. A complete quality system that adheres to CFRs has significant advantage over paper documents or even data software such as Microsoft Excel or Access, in that it would enable electronic signatures detailing each input throughout the chain, an audit trail of all records, and a date/time stamp of each step in the process. And, Dowling added, such a system locks down all entered information for a permanent audit trail that can’t be changed by someone at a later date.

As regulations stand, plants are in compliance as long as they have a paper trail tracking their product one forward one back. But, said Jack Payne, director of solutions consulting for CDC Software, "with a paper trail, there can be errors in recording the data and recovering the data." For example, the digits of a lot number could be transposed, causing a trail to error out or significantly extend in tracking time. Electronic systems prevent such errors, whether through real-time data gathering with scanners or system input which would reject an inaccurate number.

Such management systems could also track quality steps, such as validating of ingredients, compliance to standards and environmental conditions such as temperature, Payne said.

With the biosciences having gone through a similar cycle, there is a great deal to learn from that industry in documentation procedures and good manufacturing practices, he said, particularly noting "controls to make sure those practices are applied and adhered to."

This is critical because, Payne said, "You want to have proper controls in place to virtually eliminate any need for recalls." Though it seems contradictory, one of the key controls to put in place is that of mock recalls. "Being able to demonstrate mock recall capability gives me assurance that they have all their controls in place; that they have CCPs and proper auditing"

End-to-end Traceability. Electronic systems also pave the way and enable supply chain compliance to ever-increasing global standards for end-to-end traceability. They are standards that are being driven not only by regulation but by customer requirements. Within the last four years, Sparn said, there has been significant adoption of RFID tracking; it was partially driven by Walmart in the early days, and now, he said, it is everywhere.

"The key point needs to be a cooperative effort between food manufacturers, their customers—and also the regulatory agencies," Payne said. "There should be one set of regulations, one set of requirements that is a cooperative set of requirements and does what is needed for food safety."

Sparn sees such cooperation as becoming a reality in smoothing the chain of traceability. Today a system may have to talk with three or more different databases to track a product, he said. "Within five years, I really think there will be global databases, public databases." Sparn sees this as being a worldwide system, where "authorized users can log into a database on the Internet, ask about a specific item and get its pedigree."

Learning from the lessons of the life sciences industry can make the transition easier for the food industry, and a current human resources trend could simplify it even further. "One of the trends we’ve seen is that there are a lot of people moving from the life sciences to food and bringing that expertise of what they know and what they have dealt with," Dowling said.

With the ever increasing attention to food safety, the increased focus on a global, electronic traceability system is inevitable, and Dowling said she is already seeing early adopters making changes in their quality organizations to prepare for the change.

"It has to happen," Dowling said. "It’s not a ‘nice to have.’ With stricter regulatory enforcement, it must happen. It may be two years down the road. It may be five years. But it will come. It will come."

The author is Managing Editor of QA magazine. She can be reached at llupo@giemedia.com.

Explore the June 2010 Issue

Check out more from this issue and find your next story to read.

Latest from Quality Assurance & Food Safety

- FSIS to Host Virtual Public Meetings on Salmonella Framework

- Climate-Smart Soybeans Enter U.S. Market

- Yoran Imaging Introduces Thermal Imaging-Enabled System for Induction Seal Inspection and Analysis

- GDT Highlights Food Safety Solutions for Food Processing and Packaging Facilities

- FSIS Issues Public Health Alert for Ineligible Beef Tallow Products Imported from Mexico

- Wolverine Packing Co. Recalls Ground Beef Products Due to Possible E. Coli Contamination

- McDonald’s USA, Syngenta and Lopez Foods Collaborate to Help Produce Beef More Sustainably

- Divert and PG&E Announce Interconnection in California to Address Wasted Food Crisis