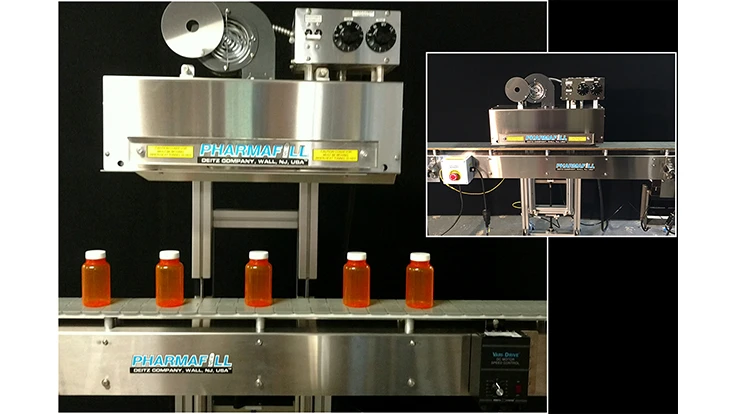

The Pharmafill HT6B Heat Tunnel from packaging machinery manufacturer, Deitz Co., features an optional Emergency Auto-Lift (EAL) that automatically raises the heat tunnel high above the conveyor in the event of a power failure and/or when the operator stops the conveyor by E-stop button. Quickly stopping the conveyor while pneumatically raising the heat tunnel, the system allows the heat to dissipate safely to prevent damage to the stopped conveyor, packaged products in process, and their tamper-evident bands. Additionally, line downtime for conveyor repair or replacement and associated costs are eliminated along with potential safety hazards and risk of product loss, the company said

The heat tunnel with the EAL system accepts bottles, cans, jars, vials, tins, and other glass, metal and plastic containers up to 10 inches high. Heating the tamper-evident neck bands with two, 3000-watt tubular heating elements, the heat tunnel quickly generates the high heat needed to shrink the plastic bands onto the bottles and retains the heat inside for continuous, energy-efficient operation at speeds up to 100 bottles per minute.

Designed and manufactured at the company's Wall, N.J., headquarters, the Pharmafill heat shrink tunnel with Emergency Auto-Lift rolls up to any conveyor and comes mounted on an adjustable-height lift stand that raises and lowers the tunnel height to match the containers being processed. The heat tunnel machine is manufactured from stainless steel and anodized aluminum for sanitary operation and does not come into contact with the bottles or other containers.

For more information, visit www.deitzco.com.

Latest from Quality Assurance & Food Safety

- Multistate Salmonella Outbreak Linked to Sweet Cream Mini Pastries

- Dr. Emilio Esteban Leaves USDA for Mérieux NutriSciences

- USDA Confirms New Strain of Bird Flu in Nevada Dairy Cattle

- Tecnologico de Monterrey Develops Nutraceutical Corn to Address Global Food Crisis

- Eurofins Healthcare Assurance Launches GMP Certification Program for Dietary and Food Supplements

- Calbee America Launches California R&D Innovation Center

- PepsiCo Completes Acquisition of Siete Foods

- Non-GMO Project Launches Non-Ultraprocessed Foods Verification