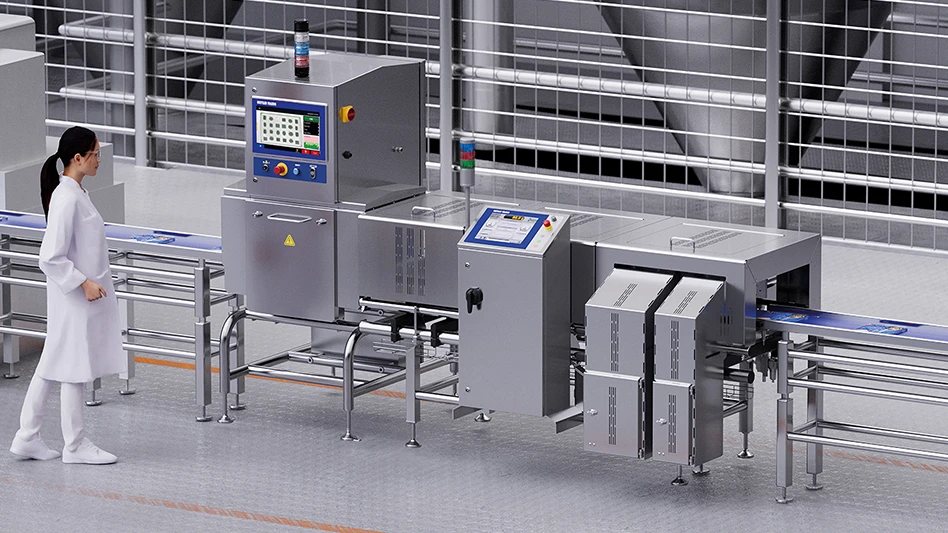

Photo courtesy Mettler-Toledo

Mettler-Toledo Product Inspection has extended its combination inspection portfolio with advances to the new CM (checkweighing and metal detection) and CX (checkweighing and x-ray) combination systems. This advancement integrates the new M30 R-Series metal detectors and X2 Series of x-ray inspection systems into C-Series checkweighers, providing customers with flexibility to choose the right system to suit their individual application, packaging and budget requirements, said the company.

With the introduction of the next generation of the CM and CX combination systems, Mettler-Toledo delivers 2-in-1 inspection solutions that manage Critical Control Points (CCPs) by combining precision weighing with contamination detection in an integrated solution. These new systems offer simplified operation, a space-saving design and reduced total cost of ownership, said the company. The integration of the new M30 R-Series and X2 Series also offers higher detection sensitivity, providing an added layer of security and quality control, said Mettler-Toledo.

According to Mettler-Toledo, key benefits of combination systems include:

- Maximum configuration flexibility: Multiple inspection combination options provide manufacturers with flexibility to find the right solution for their packaging, application and budget needs.

- Enhanced operator efficiency: One-touch operation via the checkweigher supports automated product changeovers. Statistical and status information for the contamination detection solution and checkweigher are available with a single HMI, reducing operator training requirements and minimizing the risk of user errors. The advanced HMI design improves usability.

- Space-saving design: Shared components, such as conveyors, provide space savings, and having less feet on the floor facilitates easy cleaning.

- Reduced total cost of ownership: A single vendor solution provides documentation, installation, configuration support, training and service for two technologies in one, reducing costs over the long term.

- Additional quality assurance checks: Vision inspection technology is available as an additional option, making a 3-in1 system that can provide quality control by detecting packaging defects, verifying label information and maintaining product integrity. 4-in-1 solutions are also available integrating checkweighing, metal detection, x-ray and vision inspection.

- Industry 4.0 ready: All combination systems can be connected to ProdX, a product inspection management software. This quality inspection data management system delivers digital management of product inspection equipment for real-time monitoring and food safety compliance. Visibility of the data can help improve productivity, food safety traceability and facilitate regulatory compliance.

“We are excited to introduce the latest advances of the CM and CX Combination Systems to our customers,” Joern Migge, head of product and market management, Mettler-Toledo, said. “These innovative solutions provide unparalleled flexibility, enhanced efficiency and significant cost savings. By integrating the latest M30 R-Series metal detectors and X2 Series x-ray inspection systems, we are able to deliver maximum protection and quality assurance for our customers' products."

For more information, click here.

Latest from Quality Assurance & Food Safety

- Chef Robotics Introduces Pat-Down Capability for Meal Presentation and Sealing

- USDA Launches Regenerative Pilot Program

- Indoor Ag-Con Adds Food Safety Track to Conference Lineup

- IDFA Recognizes Federal Officials for Support of U.S. Dairy Industry

- Tetra Pak Acquires Bioreactors.net

- Fresh Del Monte Receives Rabobank Leadership Award

- São Paulo Earns Guinness World Record for Largest Municipal Food Security Program

- KPM Analytics Releases Ready-to-Use NIR Calibration Packages