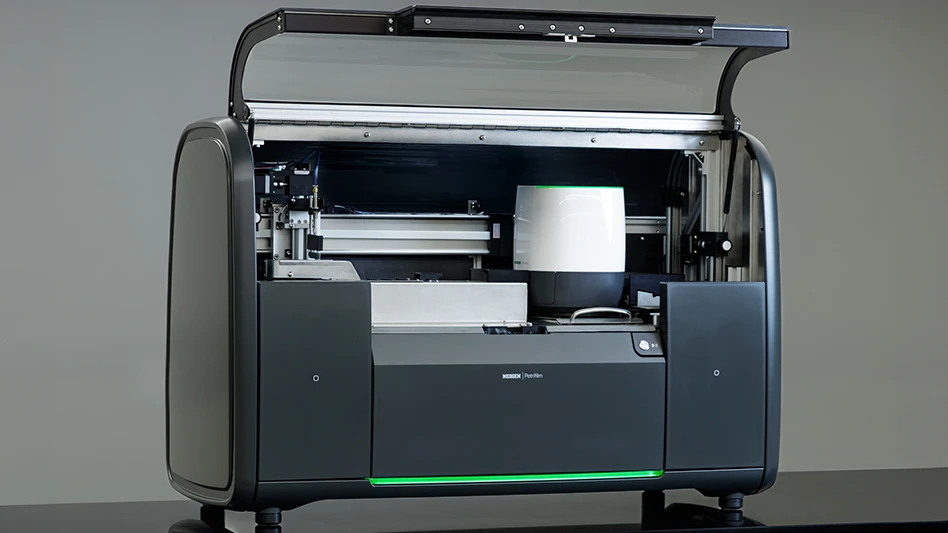

Photo courtesy Neogen

LANSING, Mich. — Neogen Corporation is striving to help high-volume food safety testing laboratories implement a more efficient way to process quality indicator tests with the launch of Petrifilm Automated Feeder, which provides indicator testing processing capabilities that build on 40 years of innovation across Petrifilm's portfolio.

The Petrifilm Automated Feeder works with existing Petrifilm Plate Reader Advanced equipment to help labs process microbial tests and meet food safety standards. It delivers consistent colony counting and improves lab productivity by automatically feeding and enumerating up to 300 Petrifilm Plates in 33 minutes while integrating with existing lab workflows and systems, said Neogen.

The system is specifically designed for high-volume food safety testing labs processing more than 100,000 quality indicator tests per year. With Neogen's automated system, technicians no longer need to manually load plates into the reader or count and record initial results. Eliminating these tasks adds capacity for these labs, allowing more time for data analysis.

"This introduction is the latest step in the history of Petrifilm innovation to help make labs more efficient and productive," said John Adent, president and CEO of Neogen. "By reducing the time burden on technician staff, Neogen is helping labs evolve and efficiently meet growing demands and to deliver safe, high-quality food while meeting testing requirements for food and ingredients. Neogen is excited to be at the forefront of investments in innovation, microbiology and food safety to evolve the modern lab."

Neogen combines hardware, software and trained AI systems to deliver an end-to-end customer testing solution. Combined, the feeder and Petrifilm Plate Reader Advanced help labs overcome challenges associated with technician turnover, human error and time-intensive training for new staff, said Neogen. It allows teams to focus on high-value tasks, automating other processes.

"The ability to load the feeder with up to 300 Petrifilm Plates and then just walk away has been a great time-saver for us," said Jon Hammond, supervisor, Midwest Labs. "The integrated software allows us to export results directly to our laboratory information management system. Now, we can spend more time on analysis and less time loading plates."

To learn more, visit info.neogen.com/PetrifilmAutomation.

Latest from Quality Assurance & Food Safety

- Multistate Salmonella Outbreak Linked to Sweet Cream Mini Pastries

- Dr. Emilio Esteban Leaves USDA for Mérieux NutriSciences

- USDA Confirms New Strain of Bird Flu in Nevada Dairy Cattle

- Tecnologico de Monterrey Develops Nutraceutical Corn to Address Global Food Crisis

- Eurofins Healthcare Assurance Launches GMP Certification Program for Dietary and Food Supplements

- Calbee America Launches California R&D Innovation Center

- PepsiCo Completes Acquisition of Siete Foods

- Non-GMO Project Launches Non-Ultraprocessed Foods Verification