OLE DOSLAND, QA & Food Safety Consultant, Certified Instructional Designer/Professional Instructor

Many food plants are large and complex, while others are small and simple. But both require sanitation activities to meet company, customer, and regulatory expectations for lowering the risk of releasing adulterated contaminated products into commerce. Contamination may occur as chemical (e.g., cleaning compounds), physical (e.g., insects), and microbiological (e.g., bacteria). In an environment where cleaning may require production downtime, time is a significant cost to the manufacturer.

Sanitation managers usually have limited budgets and must be efficient and effective in their efforts. Efficient sanitation is based on science and is complex. Efficient is commonly defined as working quickly and effectively in an organized manner bringing about a desired result with little waste. The food facility, structures, environment, equipment, tools, and utensils must be cleaned and sanitized at the right time in the right way. For example, under-cleaning increases the risk of contamination, over-cleaning creates an unnecessary cost, and wrong cleaning can create contamination which may lead to a product recall.

SANITATION IMPACTS. Sanitation has a direct impact on managing pests, especially insects; controlling microorganisms, especially pathogenic bacteria; and preventing slips, trips, and falls. Effective cleaning is an ongoing balancing act to prevent contamination while combating the varying consequences of soil and time. Sanitation is a key part of Good Manufacturing Practices (GMPs) and an essential prerequisite for a Hazard Analysis Critical Control Point (HACCP) and Hazard Analysis Risk-based Preventive Control (HARPC) programs, in addition to being a Food Safety Modernization Act (FSMA) required preventive control. Sanitation is a challenge and will always face scrutiny by companies, customers, third parties, and regulatory personnel.

Although sanitation issues can lead to regulatory action, an effective sanitation program will impact allergen, microbiological, pest, and safety activities within a food plant. Food industry personnel must understand the why, how often, and how of assuring the manufacture of safe food products, while protecting employees and property in carrying out sanitation tasks. The why and how often should be a well thought-out process in preventing allergen, microbiological, pest, and safety issues.

UNDERSTANDING SANITATION. Understanding sanitation begins with understanding basic practices, common words, and concepts. Sanitation generally refers to the maintenance of hygienic conditions with a series of activities and programs to accomplish such conditions.

Sanitation utilizes two basic activities: (1) cleaning to remove food debris, organic material, and soil; (2) sanitizing to reduce microbiological organisms to a safe level. Rarely can both be accomplished simultaneously. Sanitation consists of assigned personnel engaged in such activities to ensure a plant operation will meet sanitation requirements for food facility, structures, environment, equipment, tools and utensils.

An effective sanitation program will remove food debris, organic material, and soil from areas that may support the survival or growth of microbiological organisms and insects without contaminating areas with such activity. The master cleaning schedule (MCS) and sanitary standard operating procedures (SSOP) are two key programs to guide assigned employee activities to meet desired sanitation requirements. Sanitation can be measured by a number of means such as visual inspection, microbiological testing for indicator bacteria using sponge sampling, or swabbing.

CLEANING IMPACT. Cleaning is a process of removing food debris, organic material, and soil from a surface. The right cleaning agent and method must be selected because not all can be used on food-contact surfaces. A food-contact surface is a surface of equipment or utensil with which food normally comes into contact. The type and frequency of cleaning depends on the complexity of the process, equipment design, and soil type.

CLEANING TYPES. There are three basic cleaning types:

- Regular cleaning provides normal, frequent, unscheduled cleaning. Ongoing cleaning during production is fundamental to any sanitation program. However, cleaning during production must not contaminate product with debris. The better one cleans during production, the better the sanitation program. Sometimes regular cleaning can appear to be good but actually only be creating an illusion of food safety-level clean.

- Maintenance cleaning provides scheduled and unscheduled upkeep for normal and food safety-level clean. Scheduled upkeep will occur in the form of a preventive maintenance program and, in some cases, it may require disassembly, service, cleaning, and reassembly of equipment. Unscheduled maintenance cleaning can occur in the form of equipment malfunction resulting in having to fix a problem or clean a spill.

- Deep cleaning typically provides a scheduled and less frequent food safety-level clean. Food safety clean is intensified reaching of the niche areas of structures, environment, equipment, tools, and utensils and getting deep into cracks, crevices, and pores generally not reached during the normal or maintenance types. Improper cleaning of niche areas can create food safety issues and must be cleaned using appropriate methods and chemicals. Deep cleaning is often performed during an entire food plant shutdown in conjunction with preventive equipment maintenance followed by pest management.

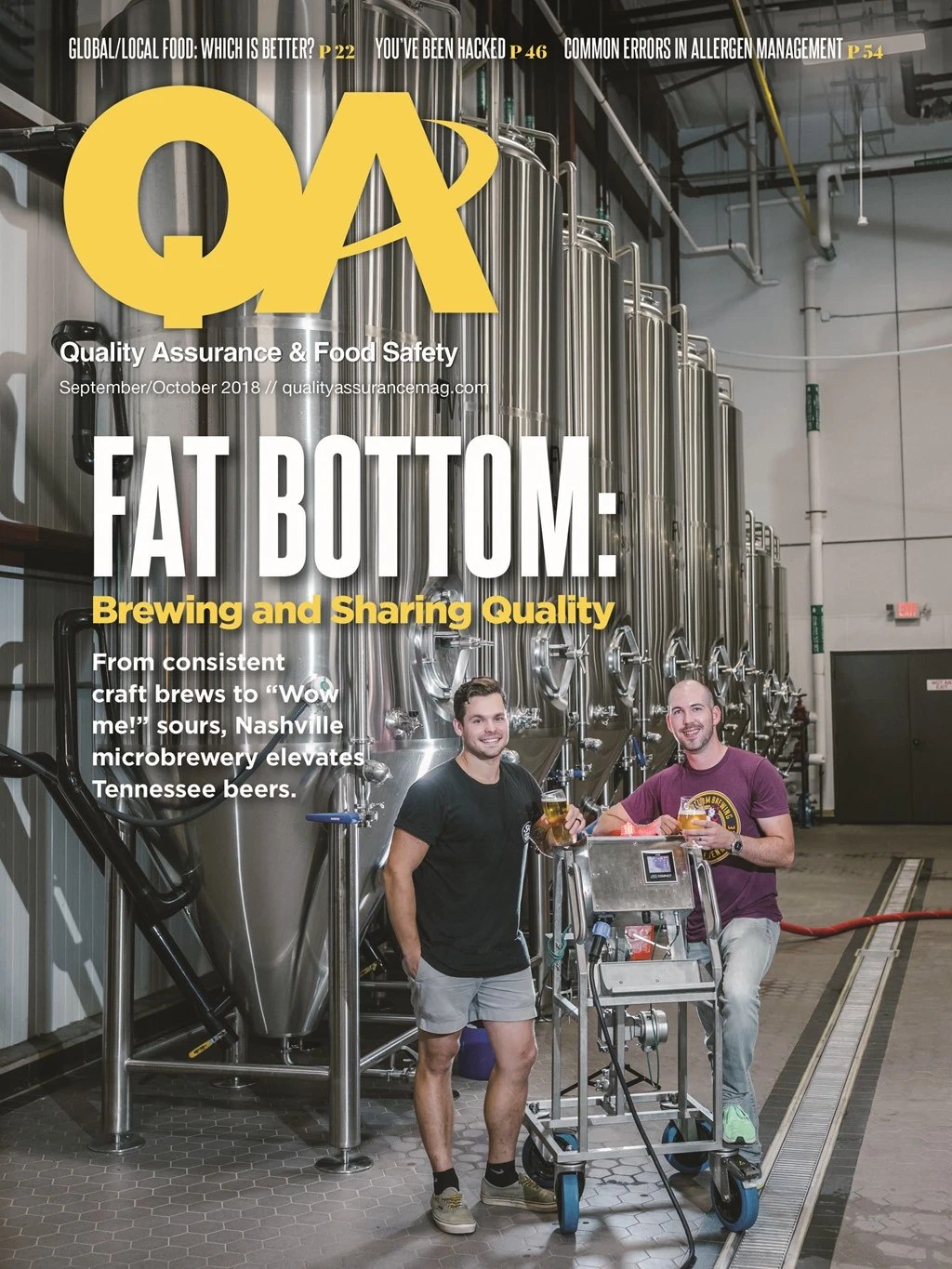

Explore the October 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Quality Assurance & Food Safety

- Chef Robotics Introduces Pat-Down Capability for Meal Presentation and Sealing

- USDA Launches Regenerative Pilot Program

- Indoor Ag-Con Adds Food Safety Track to Conference Lineup

- IDFA Recognizes Federal Officials for Support of U.S. Dairy Industry

- Tetra Pak Acquires Bioreactors.net

- Fresh Del Monte Receives Rabobank Leadership Award

- São Paulo Earns Guinness World Record for Largest Municipal Food Security Program

- KPM Analytics Releases Ready-to-Use NIR Calibration Packages